Products

Service Tel:+86-133 7364 6828

Service Tel:+86-133 7364 6828

Service Tel:+86-133 7364 6828

Service Tel:+86-133 7364 6828

Products

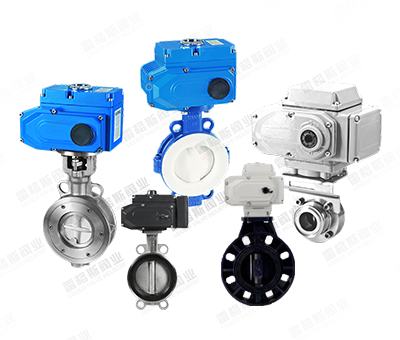

Nominal diameter: DN25-DN1000

Pressure range: PN10/PN16/5K/10K/150LB

Operating temperature: -20℃ to 120℃

Valve body: ductile iron, cast steel, stainless steel

Valve disc: cast steel, stainless steel, nickel alloy

Features: Bidirectional sealing with zero leakage, pinless structure

Medium: gas, liquid, powder, etc

Overview:

The pneumatic butterfly valve is composed of a valve stem, valve body, valve plate, valve seat and pneumatic actuator, etc. When the pneumatic actuator receives a signal from the control system, it transmits power to the valve stem through compressed air or other gases, causing the valve plate to rotate and thereby changing the on-off state of the valve. The soft sealing design and structure of the valve seat enable the valve to have good sealing performance in the closed state, and it is widely used in the fluid control system in the industrial production process.

Nominal diameter: DN15-DN200

Valve body material: carbon steel, stainless steel, special alloys, etc

Control methods: Switch type, regulating type, straight-through, three-way, multi-channel

Working principle:

Pneumatic ball valves rely on pneumatic actuators to drive the rotation of the ball to achieve the opening and closing of the valve. When the control air source enters the cylinder of the pneumatic actuator, it pushes the piston to move. Through the transmission mechanism such as rack and pinion or fork, it drives the valve stem to rotate, causing the ball to rotate 90° inside the valve body, thus achieving the opening or closing of the valve.

Application:

The products are widely used in the transportation pipelines of various petroleum and chemical raw materials and products, such as crude oil, refined oil products, and chemical liquids for flow control and shut-off.

Nominal diameter: DN25-DN200

Valve body material: WCB、ZG1Cr18Ni9Ti、Cf8(304)、CF3(304L)、ZG1Cr18Ni12Mo2Ti、CF8M(316)、CF3M(316L)

Applicable media: water, steam, oil, strong oxidizing media, corrosive media such as nitric acid, acetic acid, urea, etc

Applicable temperature: -28 ° C~425 ° C

Product performance and usage:

Pneumatic discharge valve uses compressed air to push the piston to perform linear reciprocating motion in the cylinder, thereby driving the valve stem to drive the valve disc to perform upward or downward movements, to achieve automatic opening and closing of the valve. In order to eliminate the phenomenon of residual media at the outlet of the container, it is often used as a bottom discharge and sampling function for reaction vessels, storage tanks, and other containers.

Selection of pneumatic discharge valve:

Pneumatic discharge valves are mainly used for bottom discharge of reaction vessels, storage tanks, and other containers. They are welded to the bottom of storage tanks and other containers through the flange at the bottom of the valve. Therefore, eliminating the phenomenon of residual process media at the outlet of the container is common. The pneumatic discharge valve should be correctly selected to expand upwards or downwards according to the actual working conditions. Like; For process media that are prone to crystallization or have dense concentrations, an upward expansion discharge valve is selected.

Nominal diameter: DN15-DN300

Nominal pressure: 1.0MPa to 4.0MPa

Working principle:

Using compressed air as a power source, the main control room manually or automatically triggers action commands to activate the intake and exhaust solenoid valves, supplying and discharging compressed air into the actuator. Compressed air acts on the piston or diaphragm, overcoming the frictional force of valve action and the spring force on the valve stem, driving the valve core to move up and down, and achieving the opening or closing of the valve.

Advantage:

Simple structure, easy manufacturing and maintenance; Small work schedule and short opening and closing time; Good sealing performance, low friction between sealing surfaces, and long service life; Low fluid resistance, suitable for fluids containing solid particles or high viscosity; The friction force of the sealing surface during the opening and closing process is smaller than that of the gate valve, and it is wear-resistant; Usually there is only one sealing surface, with good manufacturing process and easy maintenance.

Application: The product is widely used in industries such as petrochemicals, metallurgy, power, and environmental protection.

Nominal diameter: DN50-DN600

Valve body material: WCB, ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti

Valve cover material: WCB, 1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti

Cover material: WCB, ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti

Gate plate material: 1Cr18Ni9Ti, 1Cr18Ni12Mo2Ti

Pneumatic actuator: single-acting/double-acting

Overview:

The pneumatic knife gate valve is a linear cut-off valve. The head of the valve plate of the knife gate valve has a beveled edge, which has a certain cut-off effect on the medium. It is suitable for use in industries such as sewage, coal slurry, syrup, mud, slag-water mixture, water supply, papermaking, and mining.

Nominal diameter: DN20-DN200

Valve body material: HT200, WCB, ZG1Cr18Ni9Ti, ZG0Cr18Ni12Mo2Ti

Overview:

The pneumatic diaphragm control valve is a precise automatic control valve. It uses compressed air as the power source and, with the help of signals from related accessories such as electrical valve positioners, converters, solenoid valves, and position-holding valves, drives the valve body to move and changes the flow area between the valve core and the valve seat. So as to achieve the regulation of various process parameters such as flow rate, pressure and temperature of various fluids (such as gases, liquids and steam) in industrial processes.

Optional accessories:

Positioners, handwheel mechanisms, air filter pressure reducers, position-holding valves, etc.

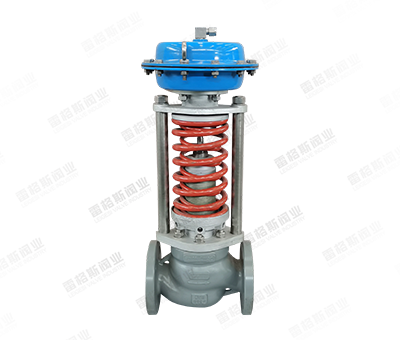

Nominal diameter: DN20-DN300

Nominal pressure: 1.6MPa, 4.0MPa, 6.4MPa

Valve body material: WCB, ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti

Material of valve core/valve seat/valve stem: 1Cr18Ni9Ti, 1Cr18Ni12Mo2Ti

Rubber diaphragms: nitrile, ethylene propylene, fluorine, oil-resistant rubber

Membrane cover: A3 and A4 steel coated with tetrafluoroethylene

Fillers: Polytetrafluoroethylene, flexible graphite

Medium used: hot water, steam, various gases and low-viscosity media

Overview:

Self-operated pressure regulating valves are a type of valve that does not require external energy sources (such as power or air sources) and achieves automatic regulation by relying on the energy of its own medium. This product can operate in environments without electricity or gas, featuring a quick-opening flow characteristic and sensitive operation. It is widely used in the automatic control systems of various equipment in the petroleum, chemical, power station, light industry, printing and dyeing industries, etc., for the pressure stabilization and automatic control of gas, liquid and steam media.

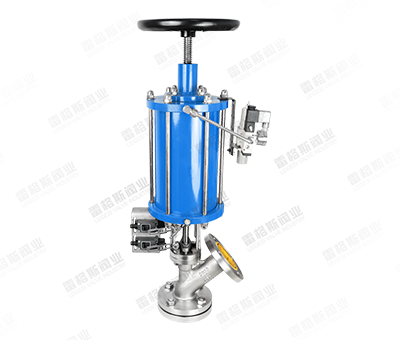

Specification: DN15-DN100

Nominal pressure: 1.6Mpa

Air source pressure: 0.3-0.8MPa

Valve body material: CF8, CF8M

Valve seat material: PTFE, PPL

Sealing ring material: NBR

Medium temperature: -20℃ to +220℃

Ambient temperature: -20℃ to +60℃

Controlled gas: Neutral gas, air

Overview:

The pneumatic Angle seat valve can save space by maintaining flow rate. It is a guided Angle seat valve operated by a single-acting pneumatic actuator with spring safety protection. When in use, it should be selected as either normally open or normally closed.

Specification: DN15 - DN50

Nominal pressure: 0-1.0MPa

Medium temperature: -20℃ to +150℃

Ambient temperature: -20℃ to +60℃

Controlled gas: Neutral gas, air

Air source pressure: 0.3-0.8MPa

Valve body material: 316L

Overview:

Pneumatic sanitary quick-installation diaphragm valves can be classified by their working forms into: normally closed pneumatic diaphragm valves, normally open pneumatic diaphragm valves and reciprocating pneumatic diaphragm valves. They are composed of piston plastic actuators and sanitary diaphragm valves and can be equipped with the following accessories according to the requirements of PLC remote control: Solenoid valve, feedback device (limit switch), positioner, air filter, handwheel, powered by compressed air at 0.4-0.6MPa, opens the valve when air enters, and automatically resets when air is cut off. Pneumatic sanitary quick-installation diaphragm valves are applied in biopharmaceuticals, biological vaccines, electronic semiconductors, pure water purification, etc.

Nominal diameter: DN50-DN1200

Pressure range: 0-1.6MPa

Operating temperature: -20℃ to +120℃

Valve body: ductile iron, cast steel, stainless steel

The control voltage: DC24V, AC24V, AC220V, AC380V.

Control functions: Switch type, regulating type

Overview:

An electric butterfly valve is a type of valve that uses a circular butterfly plate as the opening and closing component and rotates with the valve stem to open, close and regulate the fluid passage. The butterfly plate of the butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, with a rotation Angle ranging from 0° to 90°. When it rotates to 90°, the valve is in a fully open state.

Application: The products are widely used in fields such as petroleum, chemical engineering, metallurgy, and hydropower.

Specification: DN15-DN200

Nominal pressure: 0-1.6MPa

Medium temperature: -20℃ to +180℃

Ambient temperature: -20℃ to +60℃

Control power supply: AC110V, AC220V, AC380V, DC24V

Valve body material: CF8, CF8M, CF3M, 2205/2507

Valve stem material: Stainless steel

Control features: Switching type, regulating type

Overview:

Electric ball valves are driven by electric motors to rotate the ball valve, achieving flow control of the medium. They have the advantages of rapid opening and closing, good sealing performance, and long service life. They can meet the usage requirements under special working conditions such as high flow, high pressure, and high temperature, and are widely used in industries such as petroleum, chemical engineering, power, metallurgy, and water treatment.

Nominal diameter: DN20 - DN300

Nominal pressure: PN1.6, 2.5, 4.0, 6.4MPa

Valve body material: HT200, ZG230~450, ZGICr18Ni9Ti

Flange standards: GB/T9113, JB/T79

Connection forms: Flange (FF RF RTJ), welding (SW BW), thread (applicable within 1")

Overview:

Electric control valves are important actuating unit instruments in industrial automation process control. With the increasing degree of automation in the industrial field, it is being applied more and more in various industrial production areas. Compared with traditional pneumatic control valves, it has obvious advantages: electric control valves are energy-saving (consuming electricity only during operation), environmentally friendly (with no carbon emissions), and quick and convenient installation (without the need for complex pneumatic pipelines and air pump workstations). Valves are classified into three types based on the power used by the actuators they are equipped with, as well as their functions and characteristics: linear characteristic, equal percentage characteristic and parabolic characteristic.

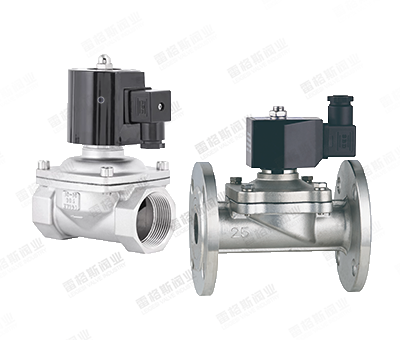

Nominal diameter: DN15 - DN50

Nominal pressure: 1.0MPa, 1.6Mpa

Applicable media: gas, water and other liquids, etc

Mode of action: Normally open/normally closed

Operating conditions: Ordinary explosion-proof

Voltage: DC24V, AC24V, AC220V

Valve body material: Cu, CF8, CF3M

Overview:

When the normally closed fluid solenoid valve is de-energized, it is in a closed state. When the coil is energized, an electromagnetic force is generated, causing the moving iron core to overcome the spring force and attract with the static iron core, thus opening the valve. When the coil is de-energized, the electromagnetic force disappears, and the moving iron core is reset under the action of the spring force, directly closing the valve. The normally open solenoid valve is the opposite. This type of valve features a simple structure and fast response speed, and is widely used in industries such as textile, printing, plastic and rubber, food machinery, and surface treatment.

Nominal diameter

Gate valve: DN15-DN300

Globe valve: DN15-DN300

Check valve: DN15-DN300

Ball valve: DN15-DN300

Butterfly valve: DN50-DN1200

Diaphragm valve: DN50-DN300

Valve body material: Stainless steel, cast steel, carbon steel, forged steel

Product Overview:

Manual valves are control components in pipeline fluid transportation systems. They are used to change the cross-sectional area of the passage and the flow direction of the medium, and have functions such as guiding flow, cutting off, regulating, throttling, checking, diverting or overflow pressure relief. Valves used for fluid control, with nominal diameters ranging from extremely small instrument valves to industrial pipeline valves with diameters up to 10 meters.

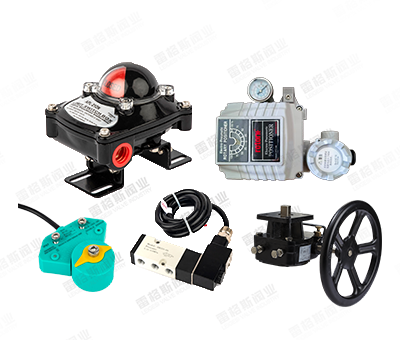

Limit switch:

APL-210, APL-300, APL-410

Solenoid valve:

Solenoid valves, explosion-proof solenoid valves, Airtac explosion-proof solenoid valves, double-control flameproof solenoid valves

Locator:

ROTORK angular travel positioner

Electric actuator

Hand operating mechanism

Horseshoe sensor feedback